Hardware cloth is a material that can be used in both industrial and horticultural operations. It is commonly used for various outdoor purposes, including controlling birds and rodents, backing for filter media, machine guarding, security screening, and many more. Its popularity and utility are due in part to its flexibility and adaptability. Read More…

We’ve been a leading manufacturer and distributor of wire cloth/mesh for 70 years, sourcing and stocking North America’s largest selection of wire cloth products – over 5000 in our warehouse. We offer processing capabilities such as precision cutting, calendering, heat treating, cleaning and coating and weave domestically most alloys including brass, copper, Hastelloy, Monel and others into ...

Dorstener Wire Tech manufactures and distributes stainless steel and nickel alloy filters and stainless-steel filter media. With one of the largest inventories of stainless-steel wire cloth in the United States, we offer the same and next-day service. We produce & supply Woven Wire Cloth, Welded Wire Mesh, Sintered Wire Cloth, Metallic Fiber Felt, and finished filter Elements. We service many...

For over 45 years, UWC has supplied quality mesh products for numerous industries with distinct applications. We maintain an extensive inventory of woven & welded wire cloth specifications. Also, our weaving capabilities allow us to manufacture various wire mesh styles. Our fabrication services comprise shearing, slitting and stamping options. In addition, we produce baskets, trays, cylinders,...

We have been creating wire mesh since 1979 and we strive to bring you the best. Our teams will help to find the perfect size and weave mesh for whatever your needs may be. There is no project too complex for Riverdale Mills Corporation. Contact our representatives to find out how we can get you started toward obtaining your goal! Our qualified staff is standing by awaiting your email, letter or...

Precision Screen Manufacturing is a leading manufacturer of wire cloth. We produce an extensive range of custom mesh, so our customers can ensure that Precision Screen Manufacturing can help with all of their wire cloth needs. With our team that has over 50 years of combined experience in the industry, we can supply a wide range of industries with wire cloth.

More Hardware Cloth Manufacturers

The wire mesh that makes up hardware cloth is organized into a grid pattern made of either woven or welded wires. Galvanized steel, stainless steel, and bare steel are possible metals for hardware cloth wire mesh.

Hardware cloth is typically categorized according to its method of manufacture (weaving or welding), the type of wire used, and how the wires meet. These are the techniques used to differentiate between several types of hardware cloth. Since hardware cloth is designed to work with specific applications, the next approach for defining it is how it will be used.

Hardware Cloth Types

Architectural Hardware Cloth

Architectural hardware cloth sees crucial use as a tool for designing and engineering buildings and structures. It serves the dual functions of being aesthetically pleasing and obstructing the outside environment while safeguarding the inside. Manufacturers make architectural hardware cloth to give architects a variety of design options.

Filtering Hardware Cloth

The robust warp wire used to create filtering hardware cloth allows it to endure the rigors of filtering and screening. Its structure makes it the best choice for separating liquids from slurries. It is simple to clean the cloth because the different weaves, such as plain Dutch, twilled Dutch, and reverse Dutch, contain more wires running in the shute direction than the warp. The high porosity of filtering hardware cloth makes it a superior filtering material to synthetic or fiber filters.

Galvanized Hardware Cloth

A zinc coating is applied during the hot dip galvanization process, creating galvanized hardware cloth. The fabric is given a protective coating during the dipping process, which makes it perfect for outdoor applications. It is a light gauge wire frequently used for pest control, construction, and fencing. Galvanized hardware cloth is lightweight, rust-resistant, waterproof, and strong. In addition, it is lightweight but offers exceptional strength, stability, and longevity.

Market Grade Hardware Cloth

Market-grade hardware cloth is woven wire in the most popular combinations and sizes. Manufacturers use a wide variety of metals to create market-grade hardware cloth. It is available in a range of openings per linear inch at hardware and home improvement stores. Market-grade hardware cloth is developed for heavy-duty use from sturdy wires like 16 and 19.

Mill Grade Hardware Cloth

Market-grade hardware fabric is heavier than mill-grade hardware cloth. It is constructed of copper, brass, aluminum, stainless steel, and aluminum. The wire diameters used in mill-grade hardware cloth, such as 23 or 27, is smaller and has fewer openings. Therefore, it is perfect for processing light materials on a screen and sifting and milling flour.

Refinery Grade Hardware Cloth

Depending on the use, refinery-grade hardware cloth is either woven or welded and is specifically made for industrial use. It is made to adhere to the strict specifications of the petroleum, natural gas, and refinery industries, where dependability and toughness are essential. Refinery-grade hardware cloth is used in various applications, including pipe fittings and catalyst support grids. Hardware cloth made for refineries has the qualities and traits of rigidity and continuous slot structure to prevent pulling and clogging.

Space Hardware Cloth

The spacing between the wires strands created during the fabrication of space hardware cloth gives it its name. Space hardware cloth is fabricated through either weaving or welding. The most popular application for this cloth is as a sifting material for gravel and sand. The cloth spacing enables precise material size, cleaning, classification, and separation.

Types of Metals Used in Making Hardware Cloth

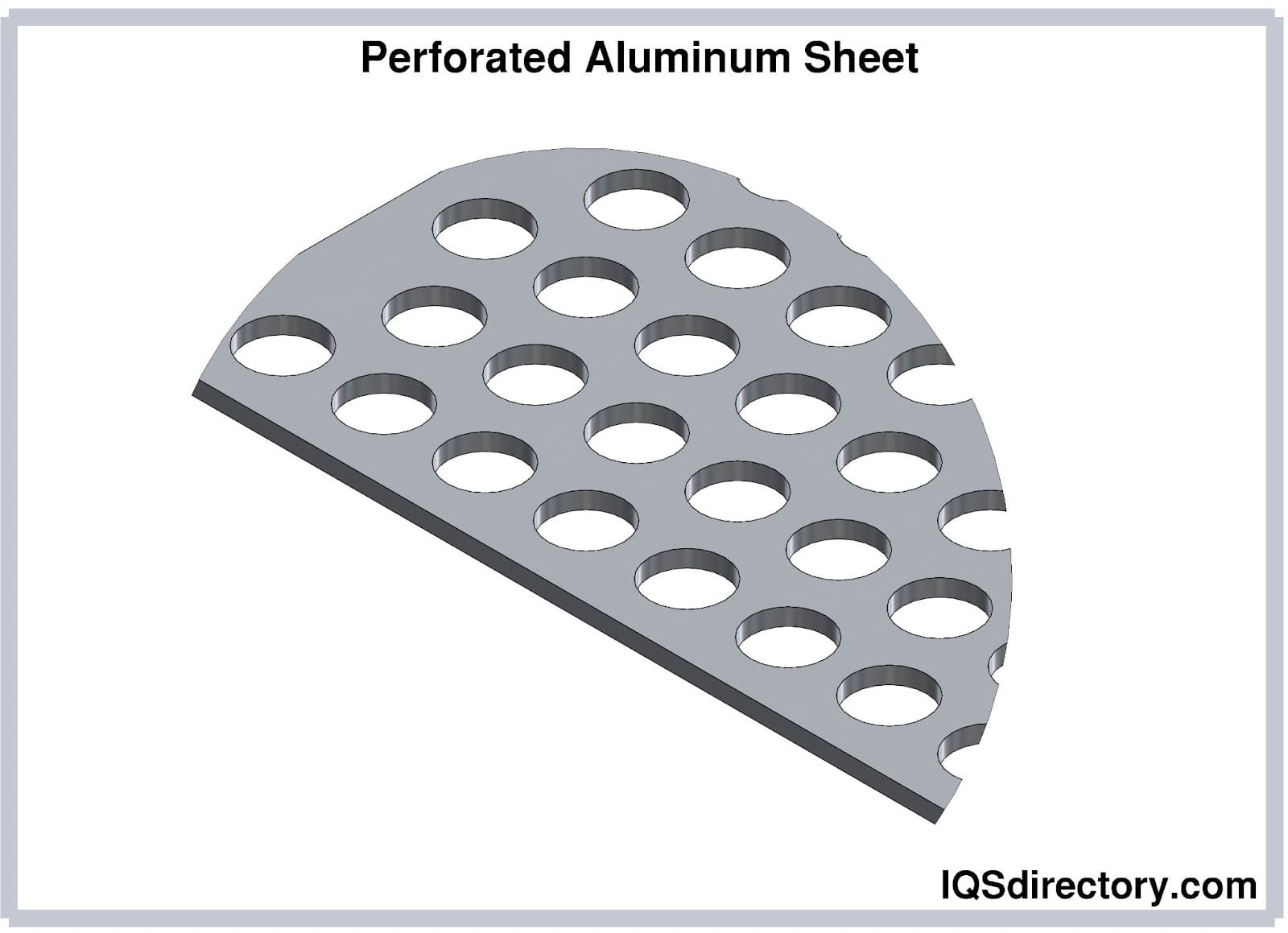

Aluminum Hardware Cloth

Aluminum has grown to be the most extensively used metal in the market since the process for refining it was developed. With a density 35% lower than steel, it has the lowest mass of all metals. In addition, aluminum has great ductility, which makes it perfect for making hardware cloth. The majority of uses for aluminum hardware cloth calls for a lightweight metal. Therefore, it is rarely used in its pure form; instead, it is typically alloyed with other harder metals to benefit from its corrosion resistance.

Nickel Hardware Cloth

Similar to aluminum, nickel is typically alloyed to improve its qualities and benefit from those of its alloys. In addition to being resistant to the impacts of acidic and chemical environments, nickel can be used in high-temperature applications. Filters and strainers for petrochemical, pharmaceutical, and chemical processes are made from nickel alloys.

Bronze Hardware Cloth

The primary component of bronze is copper, which shares many of the same traits and qualities as copper, such as malleability, ductility, and durability. 90% copper and 10% zinc are in hardware cloth made from bronze. In environments with atmospheric corrosion, such as maritime applications, bronze wire hardware cloth is employed. Similar to nickel, bronze is a material that is frequently used to make filters and separators. In addition, bronze is sometimes used in architectural applications because of its aesthetic.

Summary

Hardware cloth is a metal fabric used for animal cages, fence material, filters, and filtering screens. It is manufactured by weaving together wires of different widths to create a metal mesh.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services