Wire mesh is an industrial product made from interlocking metal wires. Wire mesh is sometimes also referred to as wire cloth, though they are not the same product in the strictest sense. Technically, wire cloth refers to those interlocking metal wire products that have been welded together in rolls on a loom, while wire mesh refers to those wires that have been sintered or welded together with evenly spaced, regular openings. Read More…

We’ve been a leading manufacturer and distributor of wire cloth/mesh for 70 years, sourcing and stocking North America’s largest selection of wire cloth products – over 5000 in our warehouse. We offer processing capabilities such as precision cutting, calendering, heat treating, cleaning and coating and weave domestically most alloys including brass, copper, Hastelloy, Monel and others into ...

Dorstener Wire Tech manufactures and distributes stainless steel and nickel alloy filters and stainless-steel filter media. With one of the largest inventories of stainless-steel wire cloth in the United States, we offer the same and next-day service. We produce & supply Woven Wire Cloth, Welded Wire Mesh, Sintered Wire Cloth, Metallic Fiber Felt, and finished filter Elements. We service many...

For over 45 years, UWC has supplied quality mesh products for numerous industries with distinct applications. We maintain an extensive inventory of woven & welded wire cloth specifications. Also, our weaving capabilities allow us to manufacture various wire mesh styles. Our fabrication services comprise shearing, slitting and stamping options. In addition, we produce baskets, trays, cylinders,...

At Phoenix Wire Cloth, we stand as a premier provider of wire mesh solutions, offering a comprehensive range of products and services tailored to meet the diverse needs of our clientele. With a steadfast commitment to excellence and innovation, we have earned a reputation as a trusted partner across various industries reliant on wire mesh for critical applications.

At Newark Wire Works, we take pride in being a trusted manufacturer of high-quality wire mesh products designed to meet the demands of industries that rely on precision, durability, and customization. With years of hands-on experience and a deep understanding of material science, we work closely with our customers to provide solutions that enhance safety, functionality, and efficiency in their...

More Wire Cloth Manufacturers

Generally, wire mesh and wire cloth are versatile industrial materials manufactured from woven, welded, or sintered interlocking metal wires. These mesh products are essential across countless industries for their unique combination of strength, flexibility, and functionality. Whether fabricated from stainless steel, galvanized steel, copper, or specialty alloys, wire mesh is a foundational component in modern manufacturing, construction, filtration, and protection systems.

Applications

Wire mesh and wire cloth serve a broad spectrum of uses in both commercial and industrial settings. Their primary applications include screening, structuring, protecting, and filtering, but their utility extends far beyond these core functions:

- EMI/FEI Shielding: Wire cloth is critical for electromagnetic interference (EMI) and frequency electromagnetic interference (FEI) shielding, protecting sensitive electronics in both consumer and industrial equipment.

- Manufacturing Belts: Wire mesh conveyor belts are used in food processing, automotive assembly, and electronics manufacturing for their durability and ease of cleaning.

- Light & Heat Diffusion: In lighting and HVAC, wire mesh acts as a diffusion medium, managing the distribution of light or heat across spaces.

- Plastic Extrusion and Watermarking: Precision wire cloth is essential in plastic extrusion processes and the creation of watermarks for currency and secure documents.

- Optical Lens Manufacturing: Fine wire mesh is used in processes demanding exact filtration and separation of materials during lens production.

Industrial applications for wire cloth and mesh are incredibly diverse, including:

- Building Window Screens and HVAC Installations

- Pulp Draining and Material Mixture Separation

- Sorting and Sifting Machinery in mining and agriculture

- Decorative Uses: Fireplace guards, kitchen cabinetry, and architectural accents

- Particle Size Analysis: Hardware cloth is used to determine and control material particle sizes by comparing them to mesh openings

Key industries benefiting from wire mesh solutions include:

- Electronics and electrical manufacturing

- Mining and mineral processing

- General industrial manufacturing

- Battery and energy storage production

- Automotive and aerospace industries

- Food and beverage processing

- Pulp and paper manufacturing

- Petrochemical processing

- HVAC and environmental engineering

- Pharmaceutical and biotechnology

- Flooring and home appliances

- Screen printing and graphic arts

Are you searching for wire mesh solutions for filtration, separation, or protection in a specific industry? Explore top-rated wire mesh manufacturers and discover tailored solutions for your application.

Products Produced

Wire mesh is the foundation for manufacturing a wide array of end products, each serving a distinct industrial or commercial purpose. The transformation typically begins with standard wire products such as:

- Wire forms and shapes

- Square mesh and diamond mesh

- Welded wire mesh and hardware cloth (both welded and galvanized)

- Woven wire mesh and fine wire cloth for filtration and separation

These standard mesh products are then fabricated into specialized items, including:

- Industrial baskets and trays for material handling

- Test sieves and flour sifters for laboratory and food industry use

- Decorative mesh for architecture and design

- Filter screens and strainers for fluid, air, or gas filtration

- Faraday cages for EMI shielding

- Protective barriers, machine guards, and safety screens

- Insect screens for residential and commercial windows

- Animal cages, chicken wire, and pet enclosures

- Window screens and door meshes

- Cooking strainers and kitchen utensils

- Floor gratings for load-bearing surfaces

- Catalytic converters and exhaust system components for automotive

Interested in custom wire mesh products for your business or project? Compare wire mesh suppliers offering bespoke fabrication and finishing services.

History

The use of wire cloth dates back to ancient civilizations, with records from Egypt where artisans hand-wove precious metals like gold and silver into ornamental cloth for jewelry. For centuries, jewelry remained the dominant use for wire weaving, showcasing both craftsmanship and material value.

By the 5th century AD, wire weaving evolved for functional uses such as armor manufacturing. Craftspeople started weaving strong metals like iron into chainmail, a revolutionary form of body armor that improved both protection and mobility for soldiers. This innovation rapidly spread across Europe, inspiring the development of wireforming for everyday utility items such as chains, hooks, mousetraps, birdcages, and window grills.

The Industrial Revolution marked a turning point in the mass production of wire mesh. The invention of steam-powered wire weaving looms enabled faster and higher-volume manufacturing, making wire cloth accessible for new applications:

- Wire cloth-reinforced sails in the maritime industry

- Flame-gauze and wire cloth gauge in mining

- Fine wire mesh screens in the paper industry

During the 20th century, especially in World War II, wire mesh found critical applications in military equipment, such as filters in tanks and aircraft, and in the fabrication of gas masks to protect against chemical agents.

Today, wire mesh is omnipresent, serving roles in food processing, construction, environmental protection, energy, and high-tech industries. Advancements in materials science, alongside CNC and automated manufacturing technology, have broadened both the capabilities and the range of wire mesh products available.

Curious about the evolution of wire cloth and its impact on modern industries? Learn more from expert wire mesh manufacturers.

Materials Process

Wire cloth can be fabricated from virtually any metal or alloy, allowing engineers and designers to select materials that match the performance requirements and environmental conditions of their applications. Material selection is a key decision factor in wire mesh manufacturing, directly influencing attributes like corrosion resistance, tensile strength, thermal stability, and cost-effectiveness.

Materials for wire mesh are typically grouped into:

- Corrosion-resistant metals (for harsh environments, chemicals, or outdoor use)

- General-purpose alloys (for standard and decorative applications)

- Specialty metals (for electrical, thermal, or aesthetic applications)

Corrosion Resistant Wire Mesh Materials

The most commonly used corrosion-resistant materials include:

- Stainless Steel: Offers exceptional strength, durability, and resistance to rust, chemicals, and extreme temperatures. Stainless steel mesh is widely used in food processing, pharmaceuticals, marine, and chemical processing industries.

- Galvanized Steel: Steel coated with a protective zinc layer, usually through hot-dip galvanization, to prevent rusting. Ideal for fencing, outdoor enclosures, and agricultural applications.

- High Carbon Steel: Provides natural abrasion and corrosion resistance, making it suitable for mining screens, gravel sorting, and heavy-duty sifting applications.

General Purpose and Specialty Wire Mesh Materials

- Titanium: A premium choice for applications demanding high strength-to-weight ratios, corrosion resistance in seawater, and exposure to chlorine or acids. Used in aerospace, marine, and chemical industries.

- Nickel Alloys: Such as Monel, Hastelloy, and Carpenter 20 CB-3, these alloys are engineered for resistance to challenging chemical environments.

- Brass: Known for its malleability, conductivity, and ease of fabrication. Often used in decorative mesh, plumbing filters, and electrical applications.

- Copper: Valued for superior electrical and thermal conductivity. Copper wire mesh is essential for EMI shielding, Faraday cages, and papermaking.

- Bronze: Aesthetically appealing, ductile, and resistant to corrosion, bronze mesh is often chosen for decorative and architectural applications.

Looking for a material comparison for your wire mesh project? Contact expert mesh suppliers to discuss application-specific recommendations and pricing.

Process Details

Joining

Wire mesh is manufactured using several joining and fabrication techniques, each offering unique mechanical and functional properties:

- Weaving: The most common method, where wires are interlaced at right angles using modern automated looms. Weaving patterns and crimping can be customized to produce specific mesh counts, opening sizes, and mechanical strengths. After weaving, mesh is rolled and stored for further processing.

- Welding: Intersecting wires are electrically fused at their joints to create a rigid mesh that resists unraveling and delivers superior strength. Welded wire mesh is especially suited for structural, fencing, and safety applications.

- Knitting and Sintering: Used for specialty filtration media, high-performance insulation, and flexible mesh products.

Finishing processes, such as galvanization, PVC coating, or anodizing, are frequently applied to enhance corrosion resistance, electrical insulation, or visual appeal.

Want to compare woven vs. welded wire mesh for your application? Learn more about welded wire mesh solutions.

Design

Wire mesh and wire cloth products are engineered to exacting specifications, with manufacturers customizing every aspect to meet client needs:

- Mesh Count: Number of openings per linear inch—higher mesh counts yield finer filtration, while lower counts provide strength and airflow.

- Total Open Area: Impacts permeability, flow rate, and separation efficiency—crucial for filtration, screening, and sifting.

- Wire Diameter: Dictates mesh strength, weight, and durability.

- Material Selection: Ensures compatibility with working environments (chemical resistance, temperature tolerance, etc.).

Note on Mesh Count: Mesh count in wire cloth is analogous to thread count in textiles, defining the number and size of openings. For example, hardware cloth with a low mesh count is favored for animal cages and fencing, while high-count mesh is essential for precise filtration in laboratories and chemical processing.

Patterns

Manufacturers offer a variety of weave patterns and geometries, each tailored for specific performance characteristics:

- Plain Square Mesh: Equal shute and warp wires; versatile for most general applications.

- Plain Dutch Weave: Dense, with smaller shute wires; ideal for fine filtration and separation.

- Twill Dutch Weave: Enhanced structural support and filtration precision; popular in automotive, chemical, and paint industries.

- Hexagon (Chicken Wire), Square, and Rectangle Meshes: Used where visibility and airflow are needed but access must be controlled (e.g., protective screens, animal enclosures).

Customization

Wire mesh manufacturers can customize:

- Material types and grades (stainless, galvanized, copper, brass, etc.)

- Mesh counts and opening sizes

- Wire diameters (measured in millimeters or gauge)

- Specialty weaves and patterns

- Coatings (PVC, epoxy, zinc, etc.) for added durability or specific environments

- Crimping styles for enhanced rigidity or flexibility

In critical industries such as petrochemical processing, pharmaceuticals, and food & beverage, strict material and process standards apply. Sintered wire mesh (particularly at large gauges) is valued for its exceptional stability in bulk goods transport and powder processing.

Need help specifying the right wire mesh design for your project? Consult with a wire mesh design specialist today.

Machinery Used

Wire cloth manufacturing employs advanced, automated looms and machinery capable of producing mesh in a variety of patterns, sizes, and wire gauges. Key machine parameters include:

- Crankshaft rotation speed

- Motor power and efficiency

- Supported mesh count ranges

- Weaving capabilities for different materials and wire diameters

- Precision control of hole dimensions and mesh width

- Adaptability for stainless steel, galvanized steel, and non-ferrous metals

Quality control systems, laser measurement, and computer-aided design (CAD) integration ensure consistent production of high-performance mesh products.

Want to learn more about wire mesh manufacturing technology? Reach out to leading wire mesh producers for details on their equipment and capabilities.

Variations and Similar Processes

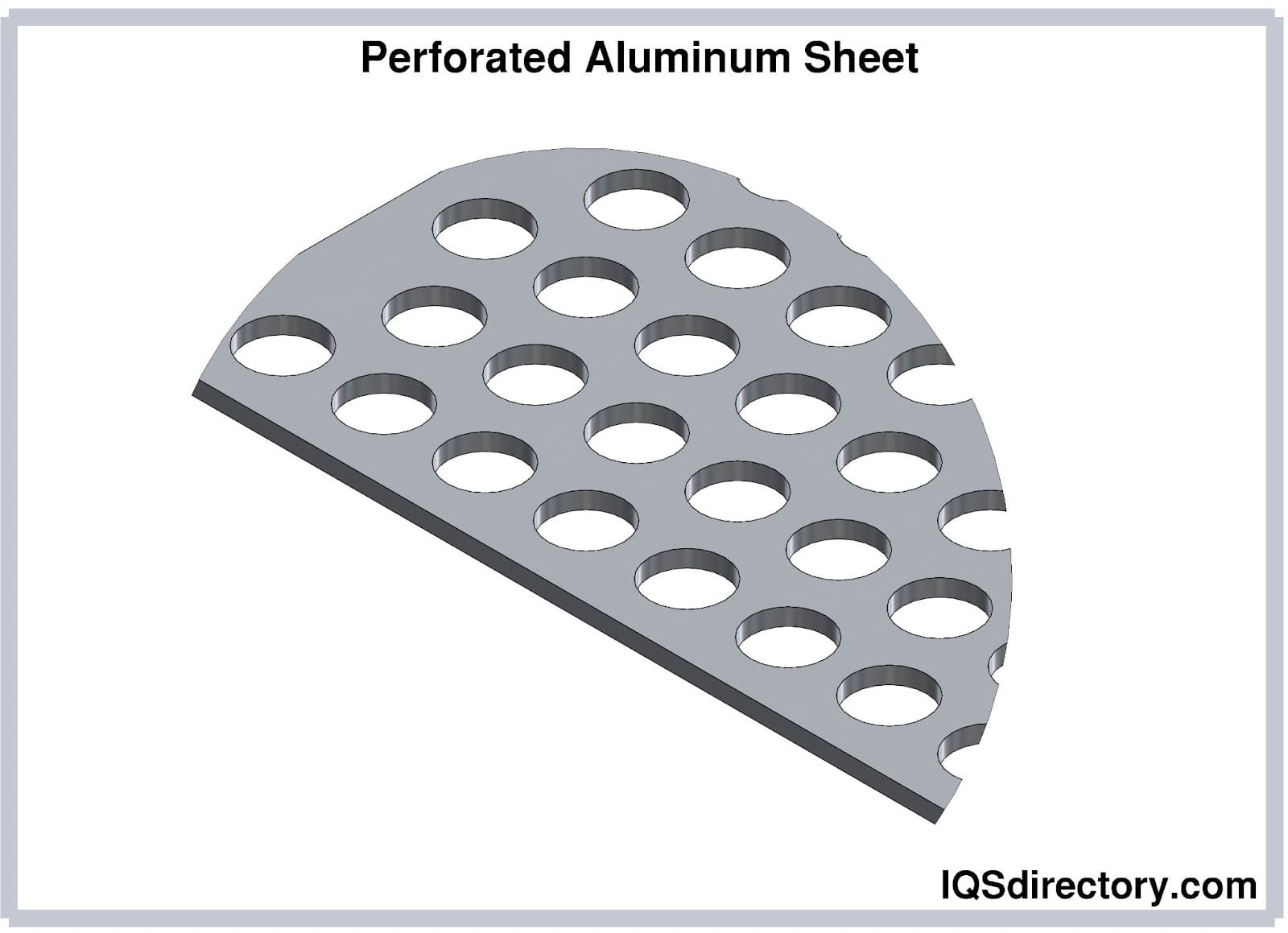

Perforated Metal

Perforated metal is a closely related product, consisting of sheet metal with pre-formed patterns of slots, holes, or decorative shapes. Produced via stamping, punching, or laser cutting, perforated metal is favored for architectural panels, filtration, soundproofing, and ventilation grilles. Unlike woven or welded mesh, perforated metal is a solid sheet with precise openings.

Expanded Metal

Expanded metal is created by cutting and stretching metal sheets to form diamond or hexagonal patterns. This process maintains the integrity of the metal while creating a mesh-like structure, commonly used for walkways, fences, grates, and machine guards.

Need to compare wire mesh vs. perforated and expanded metal for your next project? Request application guidance from mesh experts.

Benefits

Wire mesh delivers significant advantages across a range of applications:

- High Strength-to-Weight Ratio: Durable yet lightweight, ideal for structural support, safety, and transportation.

- Customizable Aperture Sizes: Enables precise control over particle, fluid, or gas passage.

- Versatility: Adaptable for filtration, separation, protection, reinforcement, and decorative purposes.

- Formability: Can be fabricated and shaped into custom forms, including cylinders, cones, and complex geometries.

- Cost-Effectiveness: Efficient manufacturing processes and long operational life deliver value across industries.

- Corrosion and Chemical Resistance: Available in a variety of materials suitable for demanding environments.

- Easy Maintenance and Cleaning: Especially important in food processing, pharmaceuticals, and HVAC systems.

Looking for cost-effective, high-performance wire mesh? Browse trusted suppliers for competitive quotes.

Things to Consider

When sourcing wire mesh, partnering with a reputable and experienced supplier is essential for achieving optimal results. Here’s a step-by-step guide to making an informed purchasing decision:

- Research and Shortlist Suppliers: Use our site’s comprehensive directory of trusted wire mesh companies, each with detailed profiles, capabilities, and product ranges.

- Compare Products and Services: Carefully review each manufacturer’s offerings, including material options, mesh types (woven, welded, expanded, perforated), customization capabilities, quality certifications, and value-added services like cutting, rolling, or special coatings.

- Request Quotes and Samples: Select three or four companies that align with your requirements, initiate discussions, and request product samples or detailed quotations tailored to your specifications.

- Evaluate Expertise and Responsiveness: Assess the supplier’s technical knowledge, responsiveness to inquiries, willingness to provide expert advice, and ability to meet standards and deadlines.

- Finalize and Place Order: Choose the supplier offering the best combination of quality, price, lead time, and customer service. Communicate your selection clearly and begin the production process.

Want to find the best wire mesh supplier for your needs? Start comparing manufacturers now and connect with industry leaders ready to deliver high-quality products on time and on budget.

Frequently Asked Questions About Wire Mesh and Wire Cloth

- What is the difference between welded and woven wire mesh?

Welded mesh is made by electrically fusing wires at their intersections for rigid strength, while woven mesh is created by interlacing wires in a pattern that offers flexibility and precise aperture control. - How do I choose the right wire mesh material?

Consider environmental factors (corrosion, temperature, chemicals), required strength, mesh opening size, and industry regulations. Stainless steel is common for corrosion resistance; galvanized steel is ideal for outdoor use; copper is used for EMI shielding. - Which mesh count should I use for filtration?

Higher mesh counts provide finer filtration, while lower mesh counts are better for structural strength and general screening. Consult with your supplier to match mesh count to your application. - Can wire mesh be customized for unique applications?

Yes, manufacturers offer custom mesh sizes, wire diameters, materials, and specialty coatings for specific operational needs. - What industries most frequently use wire mesh?

Key sectors include construction, mining, food processing, pharmaceuticals, energy, automotive, and electronics.

Next Steps: Get the Right Wire Mesh Solution

Whether you need industrial wire mesh for filtration, architectural mesh for aesthetics, or specialty mesh for advanced engineering applications, choosing the right material, weave, and supplier is crucial. Take advantage of our expert-curated directory and resources to:

- Identify the best mesh type for your use case

- Compare top-rated manufacturers and their capabilities

- Request tailored quotes and product samples

- Access technical guidance and application support

Ready to move forward? Browse our list of wire mesh manufacturers and start your project with confidence today!

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services